Assembly and service activities

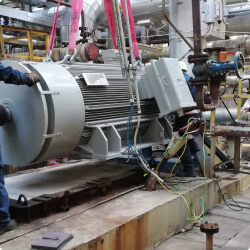

Repairs and installations of rotary machines

Ensuring service activities in the field of turbo compressors, pumps of all types, piston compressors, special machines and equipment.

Processing of complete engineering for the planning and execution of repairs, including the provision of health and safety. Ensuring cooperation and coordination of repairs with the equipment manufacturer. Ensuring specification, supply or production of spare parts. Provision of revision reports, performance of pressure and construction tests, provision of approval of performed tests by notification authorities.

Provision of auxiliary professions such as insulation, scaffolding, NDT, handling technology, etc.

Design, manufacture and installation of steel pipes

We design, manufacture and install steel pipelines. We supply the necessary pipe material, including compensators and fittings, atypical pipe parts, supports, auxiliary steel structures.

We create relevant welding and assembly documentation. We have a portfolio of welding procedure qualification reports (WPQR), based on which our welding technologist issues welding procedure specifications (WPS) for the relevant welding methods. We have a number of qualified and highly skilled welders. We design, manufacture and assemble pipes in nominal diameters from DN15 to DN1200 and in wall thicknesses from 1mm to 20mm, made of carbon and austenitic steels. We adapt the range of deliveries to the customer’s requirements – from the delivery of pipe parts, connecting material, seals to preparation of realisation project, assembly, testing and as-built documentation. Of course, we also provide the relevant steel structures, scaffolding, assembly platforms, thermal insulation, coatings, NDT and approval by an authorized person

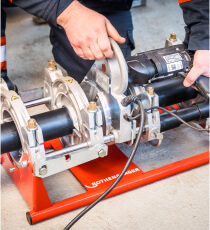

Production and installation of plastic pipes

We install plastic pipelines, including the supply of pipes, valves, fittings, expansion joints, supports and production of atypical parts.

We use different methods to join plastic pipes (butt welding, electrofusion welding, polyfusion welding, gluing, flange joints and other methods). Welds are performed according to certified WPQR (WPAR) welding procedures. We assemble pipelines from proven structural elements from various modifications of plastics: polypropylene (PP), polyethylene (PE), polyvinyl chloride (PVC), acrylonitrile-butadiene-styrene (ABS), polyvinylidene fluoride (PVDF).

The scope of delivery includes everything from the piece delivery of individual components to the comprehensive delivery of the pipeline system, including the processing of the implementation project, delivery, assembly and appropriate testing.

For the supply of plastic pipe systems, we mainly use the supplies and know-how of the Swiss manufacturer +GF+.

Maintenance and technological shutdowns

We carry out high-quality, fast, comprehensive and continuous maintenance. We also implement routine daily inspection, machine maintenance, repairs of entire production technologies.

We ensure the supply of machine parts, the implementation of technological shutdowns, intermediate and general repairs and the liquidation of accidents. If required, we carry out all repairs in the form of a „turnkey“ delivery. For each repair, the technological and assembly procedure of the repair is processed, including the determination of relevant controls and measurements, OHS and FP. Inspections and measurements are documented by measurement records, test reports, repair reports and NDT test laboratory reports. We also cooperate with an authorized material testing company (determining the mechanical properties of the material, determining the causes of mechanical damage to the material, etc.) Maintenance is carried out by a team of experienced workers with many years of experience. All employees undergo ongoing repeated education and training, including training from suppliers of special machines and equipment, whose maintenance and repairs they use.

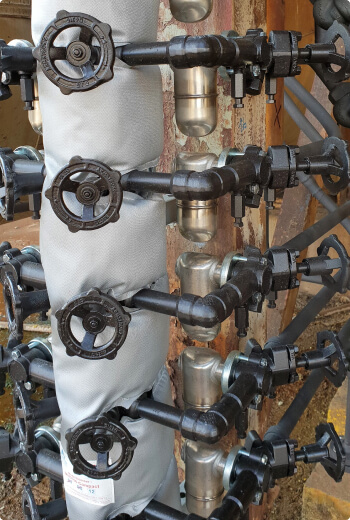

Maintenance of steam-condensate systems

Along with rising energy costs, the need for maintenance and optimization of steam-condensate systems increases. We offer you a comprehensive concept of technical solutions in the field of steam condensate systems, which will reduce your operating costs and at the same time increase the reliability of the system.

For a detailed assesment and optimization of the steam-condensate system, contact the specialists of RUML s.r.o

Technique

- Kemppi TIG and MAG electric welding sources

- Portable electric generator

- Portable lighting

- Elevating platform 23 m

- Torque wrenches

- Electric torque wrench

- Laser leveling device

- Vibration diagnostics

- Conventional machine tools (lathe, milling machine, table drill, press, saw)

- Forklift 3.2 t

- Mobile workshop, flatbeds 3.5 t

- Tractor with towbar

- Assembly containers